Our Process

Conceptualization

CP North America has 25+ years experience in delivering integrated and ruggedized systems to military and industrial/commercial standards. Based on your needs, we will design a customized system in an appropriate chassis.

Engineering

Next, our team of in-house engineers will design and rapid prototype your product off a standard COTS with your specified modifications. Our engineers are also prepared to define and manufacture custom solutions to your needs.

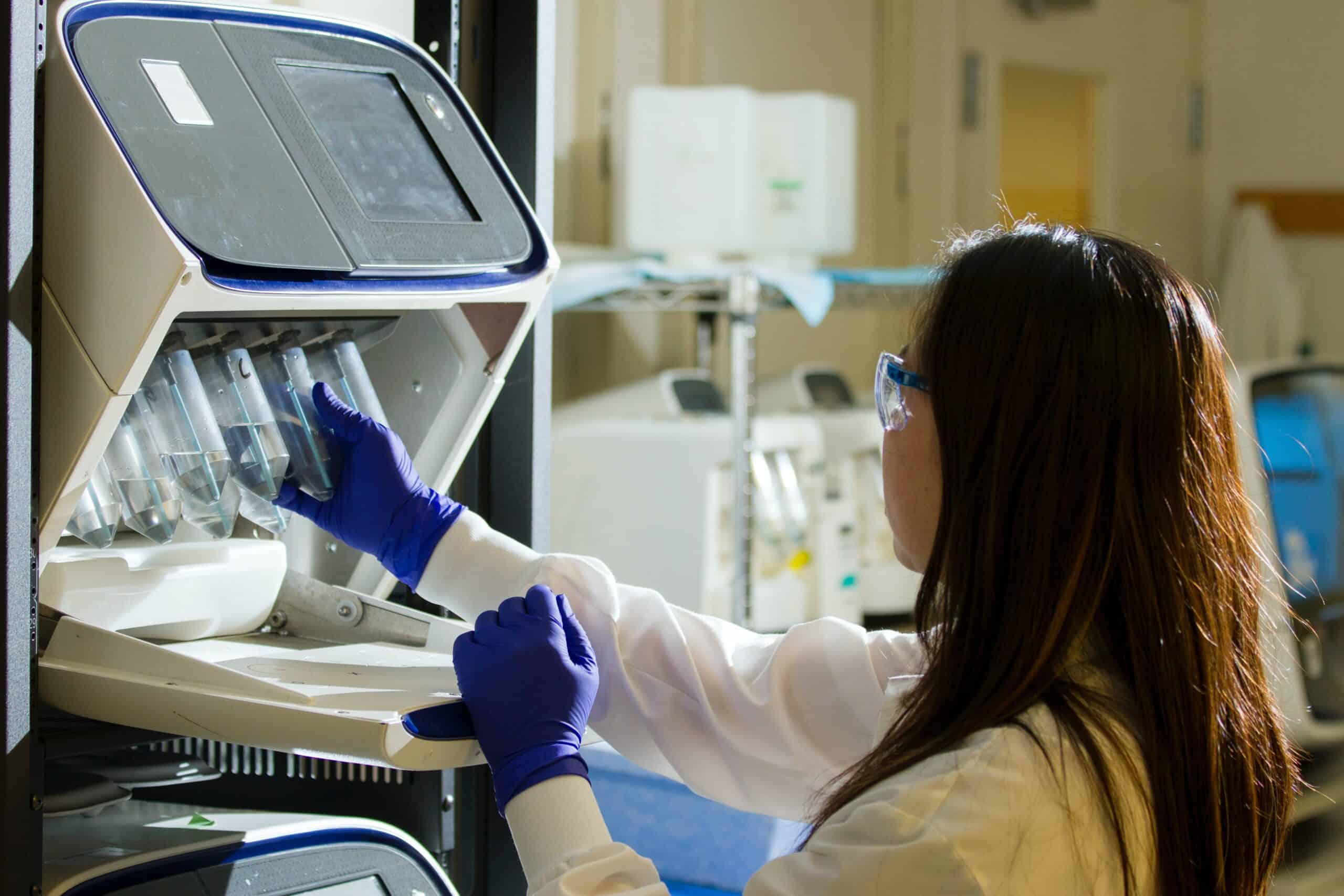

Production

After collaboration and troubleshooting, we will handle shipping and system management under a single part number. For a longer lifecycle, every system is backed by a 5-year warranty, federally-approved vendors and components, and road mapped revision control.

Why Partner with CP Tech?

CP North America has been proudly serving our nation's military and industrial needs for 25+ years. With this experience, our expertise and product focus has been in designing, manufacturing, and integrating high-performance and ruggedized computing platforms, storage arrays, and networking hardware for military and industrial sectors. Each product designed and assembled by CP North America is passed through rigorous industry-specific standards including: ISO9001:2015, IPC Certification, MIL STD-810, and is ITAR registered. Couple this with an emphasis on mitigating EOL concerns and revision control, CPNA aims to make the process of rapid prototyping-to-production as frictionless as possible.

We are also happy to announce our new cable harness/wire loom manufacturing capability with our in-house cable engineering team.

High Level In-House Capabilities for Customization

CP North America possesses an extensive staff of engineers to meet your total customization requirements, including: systems, application, product, electric, mechanical and prototype engineers. To name just some of the unique environmental requirements we have engineered for, CPNA utilizes SolidWorks modeling and testing environments for shock and vibration, storage and operating temperatures, air filtration, etc.

Further based on your needs, whether it's COTS standard products or custom-made, virtually any component is eligible for modification. Rapid prototype deliverables are often shipped within 12-18 weeks, creating low hassle and a quick deployment time.

Quality Management Every Step of the Way

Each component and system that leaves our facility is rigorously tested to the highest of standards and only received through federally approved vendors for counterfeit control and optimal function. Our production utilizes ISO9001:2015 quality management system, as well as diligent compliance with regulations and quality certifications such as: ITAR, IPC, MILSTD-810, and other industry standards.

If you have a specific set of standards you need met for your systems, contact us here.

Previous Wins