Rapid prototyping can be used to verify a design direction by testing specifications and components before committing resources. It can provide timely “proof of concept” products for review and final decision making. Rapid prototyping can help you meet a deadline if your customer suddenly backs up delivery schedules.

Rapid prototyping can be used to verify a design direction by testing specifications and components before committing resources. It can provide timely “proof of concept” products for review and final decision making. Rapid prototyping can help you meet a deadline if your customer suddenly backs up delivery schedules.

CP Technologies’ customers work on a variety of specialized programs, everything from designing a new unmanned vehicle to developing software applications. Most projects require integrating a ruggedized computer and rugged LCD displays. Our customers outsource these specialty products to us. While they focus their time on the main design challenges, we help them achieve their objectives by providing high-quality rapid prototyping of these computer systems. So we’ve found the best engineering talent possible, use the latest 3D CAD design and test software, and implemented ISO 9001 procedures to make this happen.

Engineers With Direct Manufacturing Experience

Along with lengthy experience in ruggedized computing design, many CP Technologies mechanical and electrical engineers also have direct experience with manufacturing. This gives our products superior design and greater manufacturability. Our engineers’ knowledge of designing rugged computers and rugged displays, plus knowing when a part can be re-used, modified or designed from scratch, can be critical factors during the rapid prototype phase.

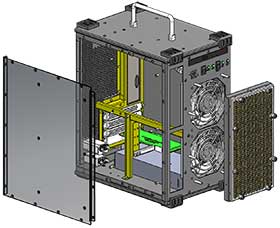

Using the latest in 3D modeling software, our engineers can design at a higher level of detail and complexity compared to working in 2D. When designing in three dimensions, the software checks for part fit and mechanical tolerances in real time. Computer modeling helps us address most design issues before parts or systems are made. From temperature simulations to shock and vibration, we can also simulate how rugged systems may perform in their intended environments. This means we can address any issues during the design phase, instead of making several prototypes to “iron out” design details. This saves us, and our customers, a tremendous amount in time and cost.

ISO 9001 To Match Customers’ Quality Needs

Managing several projects concurrently, while handling customer and vendor communication and maintaining on-time delivery schedules, led us to implement ISO 9001 procedures. We constantly work to improve our quality procedures, because each customer has different requirements. Since both military and industrial customers require ISO standards, this ensures that CP Technologies’ operational practices align with our customers’ practices.

A Customer with Serious Challenges and Little Time to Resolve Them

Recently, a company’s design team contacted us after discovering a problem 8 weeks before the first scheduled delivery to their customer. The team found out that the hardware running its software application needed a rugged 5U GPU server and rugged storage array to operate in a harsh desert environment. Several competitors had quoted 12- to 14-week lead times. By the time the team called us, it needed a 5-week turnaround to give enough time for final integration and testing.

This time, as whenever CP Technologies quotes unique or custom ruggedized hardware, we assembled our own team that included the heads of engineering, operations, and sales. We laid out a timeline, assigned tasks, set project milestones, and managed employees to the agreed-on timelines.

Expertise Plus Reuse of Proven Designs

For this customer, we recommended changes to the hardware platform that increased system performance, as well as revision-controlled and long-life system components for streamlined manufacturability. We also recommended design simplification by modifying an existing, proven CP Technologies standard ruggedized enclosure. This meant the majority of the design was already complete and only required modifications to fit the customer’s project requirements.

Concurrently with our design team, the CP Technologies systems integration team ordered the required revision controlled components and began testing to verify the new hardware combination for mechanical form and function, hardware/software compatibility, and system performance. These integrators hand their knowledge and experience to the manufacturing group via meticulous documentation, ensuring that each system is built to the exact specifications. In this case, most work was completed in advance, so the systems needed could be assembled, tested, and shipped within the 5-week window our customer requested. These efforts allowed the customer to deliver their product on time to their customer, and let us become a valued member of their team.