MIL-STD-810G – What it is

This CP Technologies White Paper discusses MIL-STD-810G. The entire Standard is available for download at MIL-STD-810G Download.

What is the purpose of MIL-STD-810? The standard states “…the environmental management and engineering processes described in this standard can be of enormous value in generating confidence in the environmental worthiness and overall durability of materiel system design.” What does that mean and how are vendors applying the standard?

One must understand that MIL-STD-810 is not a specification per se but a standard. A specification provides for absolute criteria which must be satisfied to “meet the spec”. MIL-STD-810 as a standard provides methods for testing material for use in various environments but provides no absolute environmental limits. MIL-STD-810 is simply a collection of recommended tests and procedures to confirm that an item being tested will perform its function reliably under certain stated conditions.

With a test plan in place, the item is tested per the recommendations of the standard and the test plan, operationally examined, and the test results documented. For example, the Program Manager and vendor can agree the item will be used in a humidity- and temperature-controlled environment at sea level, devise a test plan to assure function in those conditions, and “meet MIL-STD-810G”. Not exactly what most people think of when they consider MIL-STD-810G.

Example

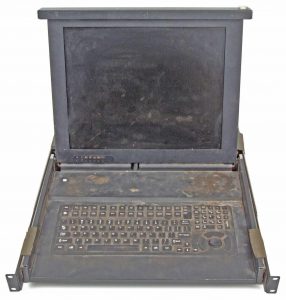

The following photos can demonstrate the value of MIL-STD-810 testing. The photo on the left is a new CP Technologies’ CCX-19 display which has just come back from a test lab. The last test performed was Method 510.5 for Blowing Sand and Dust. The photo on the right is a similar display which has been returned to CP Technologies for refurbishment after being deployed in Afghanistan. The damage to the two displays looks to be identical except the display on the right has what appears to be soda or coffee stains from the operators setting their drinks above the keyboard. By performing the 810G tests, there is a high degree of confidence the displays will perform in the very harsh and dirty battle field environment as demonstrated by the display on the right.

What is in 810G?

MIL-STD-810G is divided into three parts:

Part One: Environmental Engineering Program Guidelines at 63 pages.

Part Two: Laboratory Test Methods at 683 pages.

Part Three: World Climatic Regions – Guidance which is new to 810G at 52 pages.

Part One discusses the roll of the acquisition team and lays out a disciplined, tailored approach for acquiring systems that will withstand the stresses of climatic, shock and vibration environments that this equipment is expect to see in its service life.

Part Two details the 28 test Methods which comprise the bulk of the Standard. A Method is a section of the Standard detailing a particular environmental condition such as altitude, high temperature, etc., and suggested testing to ensure a device will survive in the required environment.

Part Three provides planning guidance for realistic consideration of climatic conditions around the world.

There are 28 Methods included in Part Two of 810G with 5 new Methods since revision F. The decimal number references the Method revision.

What MIL-STD-810G brings to the table for most companies is the experience of specifying a test program. For example, what temperatures would be experienced in a desert setting? The customer and vendor could research and make an educated guess as to the temperature environment in, say, Afghanistan. Or they can simply take advantage of the work that has gone into MIL-STD-810G and the previous revisions where these high and low temperature extremes are documented.

CP Technologies manufactures rackmount and transit case mounted computers and LCD displays. As such, the appropriate test Methods they test to and which are appropriate for manufacturers of similar devices are highlighted in the following list of Methods. Additional information for each Method can be accessed by clicking on the link.

* 500.5 Low Pressure (Altitude)

* 501.5 High Temperature

* 502.5 Low Temperature

* 503.5 Temperature Shock

504.1 Contamination by Fluids

505.5 Solar Radiation (Sunshine)

506.5 Rain

* 507.5 Humidity

508.6 Fungus

509.5 Salt Fog

* 510.5 Sand and Dust

511.5 Explosive Atmosphere

512.5 Immersion

513.6 Acceleration

* 514.6 Vibration

515.6 Acoustic Noise

* 516.6 Shock

517.1 Pyroshock

518.1 Acidic Atmosphere

519.6 Gunfire Shock

520.3 Temperature, Humidity, Vibration, and Altitude

521.3 Icing/Freezing Rain

522.1 Ballistic Shock

523.3 Vibro-Acoustic/Temperature

524 Freeze / Thaw

525 Time Waveform Replication

526 Rail Impact

527 Multi-Exciter

528 Mechanical Vibrations of Shipboard Equipment

Many of these Methods are fairly straight forward. For example, Method 500.5, Low Pressure, is used to simulate high altitudes for high ground elevation sites or transportation in aircraft. The Method is also applicable to rapid or explosive decompression. For the tests, the item is placed in a pressure chamber which allows the pressure to be lowered to simulate high altitudes. Failure modes of the equipment may include fluid leakage, electrical arcing, mechanical distortion, and so forth.

Other Methods can be quit complex. For example, Method 522.1, Ballistic Shock, discusses shock propagation through a vehicle in which electronics may be installed. The physics of such shock propagation are not particularly well understood and simulation can be difficult and misleading. The best way to perform the test may be to mount the equipment in the actual vehicle and shoot it with appropriate non-exploding ammunition. This is an expensive test and generally not available at civilian test labs.

RFQ Specification Confusion

Often an opportunity to bid will be posted by a military customer wherein the statement “Must meet MIL-STD-810G” is included. What exactly does that mean? There are 28 distinctly different Methods included in 810G. Perhaps a major program such as the F35 Joint Strike Fighter will be tested to most of the 28 Methods but will it be subjected to Method 526 for Rail Impact (for transport on rail cars)? Items such as rackmount computers or LCD displays should be tested to an appropriate sub-set of Methods but certain Methods, such as Method 509.5 (Salt Fog), are certainly not applicable and would destroy the unit under test. On the other hand, a sealed fanless computer might have a requirement to be tested for Salt Fog and it would survive. What Methods in MIL-STD-810G the customer wants the product to meet should be documented within the RFQ?

To be accurate, a vendor should reference the Method(s) and limits their device was tested to. Pre-testing may be sufficient to satisfy a Program Manager’s requirements in which case the product would be in conformance with the Standard. “Designed to Meet” can be construed as a statement by the company’s engineers that they have made their best efforts to assure the design will conform with appropriate parts of the Standard but, until the item is actually tested, there are no guarantees. In any case, a product cannot “meet” MIL-STD-810G without input from the customer to determine which Methods and environmental considerations are appropriate for their particular program. It is legitimate to state a product has been tested per Method ‘xxx’ with stated conditions to indicate to interested customers the product has a chance of surviving in the field.

Conclusion

Like it or not, MIL-STD-810 is here to stay and will be updated periodically as new requirements, technology, testing methods and computational analysis capabilities are introduced. There transpired 11 years between revisions E and F and 8 years between revisions F and G. Program Managers need to communicate their testing requirements more clearly. Contracting Officers need to quit using a broad “Meets MIL-STD-810G” requirement. Vendors need to be forthcoming with what Methods in 810 they have actually tested to. “Designed to Meet” doesn’t really mean much given that compliance with 810G is a contract between a customer and vendor. MIL-STD-810 binds two entities together in a complex relationship for the greater good.

MIL-STD-810G is a compendium of suggested tests and not an absolute specification to which assemblies can be tested and said to “meet the spec”. The Standard is 804 pages of the collected wisdom and experience of many engineers over many years verifying that military equipment will function reliably in the incredibly harsh conditions of the battle field.

CP Technologies offers military grade computers, LCD displays and Zero Clients, many of which which have been tested per MIL-STD-810G. Working closely with multiple customers, CP Technologies has tested various products to the requirements of MIL-STD-810G to meet the customer’s specific application and mission requirements. They have also proactively tested several products to appropriate parts of 810G to demonstrate to potential clients the systems would pass formal testing.