Successfully Building a Rapid Prototype

For many suppliers to large military and industrial contractors the idea of a rugged computer hardware and all that it entails may be a relatively unfamiliar topic, especially when it involves fulfilling the numerous Department of Defense requirements that may be involved in a military program. When approaching a project from the software perspective, which mainly defines the system’s functionality and usefulness to the customer, it is easy to lose sight of the complexity and detailed hardware specifications that are essential to its actual ability to function reliably in the application environment. That environment could be airborne, a tactical operation center, a military vehicle or a shipboard application.

We’ve all heard of defense standards, or MIL-STDs, that are required for contractors to meet, but how to fulfill them and reliably document them for a rugged computer system to meet the needs of the customer is not straightforward. Rather, it is one of detail, specialized design, and strict configuration management. While the underlying architecture may be that of the familiar PC, its actual physical design and internal construction may have to meet a variety of strict size, weight, power, security and environmental requirements; all of which must be carefully documented and certified.

We’ve all heard of defense standards, or MIL-STDs, that are required for contractors to meet, but how to fulfill them and reliably document them for a rugged computer system to meet the needs of the customer is not straightforward. Rather, it is one of detail, specialized design, and strict configuration management. While the underlying architecture may be that of the familiar PC, its actual physical design and internal construction may have to meet a variety of strict size, weight, power, security and environmental requirements; all of which must be carefully documented and certified.

This was the experience of one CP Technologies customer who had just won a military contract for a system based on its persistent surveillance software. During initial laboratory testing the software was working fine, but the commercial grade computers used for development were failing in the field due to dirt and dust, seriously threatening the cancellation of the contract. Even with the short time (8 weeks) given to come up with a rugged solution or lose the contract, the customer was able to work with CP Technologies to find a solution in time. Being aware of the steps and procedures involved in custom, rugged, product design may help future customers avoid such a costly situation.

First, it is important to realize that designing a rugged computer involves more than just the enclosure but also the selection and certification of components (processors, peripherals, drives, connectors, boards, etc.) and their assembly into the rugged design. For that it is first necessary to understand—and for the customer to fully comprehend—what overall goal they are actually trying to achieve. With over 20 years of experience, CP Technologies has a number of combat proven products that may very well fit the bill or require only a few modifications to do so (Figure 1). A large library of proven designs is also available to assemble and configure into a custom design so that it is never necessary to start totally from scratch to meet those requirements once they are understood. CP refers to this as MOTS- Modified Off The Shelf.

The first step is to engage in detailed consultation with the customer to understand exactly what they want to do. “Rugged” gets translated into “how rugged” in terms of shock and vibration. This varies between a shipboard, airborne or ground based application. The same is done for temperature range and a host of other parameters leading to the creation of a “technical resources document” that contains this information along with processor, memory, hard drive, etc., along with blanks to fill in unusual information or requirements. This can then lead to the specification of the nature of the chassis required. At this point, the process also identifies the customer’s required project timeline and makes sure that the customer understands the test procedures and data that will be needed to meet the requirements, at which point there can be an actual quote.

Getting there, however, requires starting with the careful selection of components. Since CP Technologies is primarily an integrator of COTS hardware, this means selecting boards that contain qualified components. One of the important qualifications is that components may not come from countries not on the Trade Agreement Act (TAA) Designated Country list, which excludes components manufactured in China, Russia, or Pakistan, to name a few This means carefully qualifying distributors to make sure their acquisition of components can be reliably traced, all of which must be documented. Clearly identifying the manufacturer is also needed for counterfeit prevention—positively identifying the manufacturer—which is not a simple matter, but one with which CP Technologies has considerable experience. It should also allow determination of mean time between failures (MTBF) as well as a roadmap of that component’s market life and the identification of follow-on devices to extend it, which are also obtained from the manufacturer.

Other requirements include a conflict minerals statement certifying that raw minerals used in parts do not include minerals mined in countries experiencing conflict including the Democratic Republic of the Congo and surrounding countries using slave labor among other human rights violations. For security, there must also be a letter of volatility which certifies which memory devices, when powered down, do not retain any data content, are, in fact “volatile,” and identify any memory areas on any devices such as processors or video controllers that may contain nonvolatile pieces of memory that could theoretically store malicious content. The requirements for environmental, temperature and shock and vibration testing will also be included.

The ability to do all this detailed selection and certification is extremely valuable when presenting the project to a large customer like Lockheed Martin or Boeing, which have groups of individuals who must check and confirm that the requirements have been met. A high quality of assurance means a smoother acceptance of the project, a shorter timeline and higher customer confidence.

The generation of all this information is of course also necessary to the start of the actual project including the scope of work—outlining what the project will entail and understanding the ultimate objective. Of course, changes can come up and the scope can be modified, which will have effects on price and lead time. So, it is important that there be an initial agreement and that any changes be clearly defined and signed off on so that everyone remains in agreement and any changes can be documented from start to finish.

Cooperative project management means that CP Technologies will have one of its Program Managers assigned to the project to quickly engage with the customer should any issues arise. This can greatly speed up the process of identifying and making any needed changes and generally facilitating communication during the project making sure that everyone is on the same page.

The Engineering Phase

In the case of the customer given a very limited time to come up with a rugged surveillance solution, the quick evaluation of system performance and environmental requirements let CP Technologies’ experienced engineering team immediately address the problem and begin work on a solution. This was possible by leveraging CP Technologies’ vast 20+ year design library containing thousands of designs covering all manner of shapes, sizes, and board configurations, many of which are already MIL-STD certified. In fact, CP Technologies has a spectrum of solutions that never requires starting from scratch. There is a range of existing products that either off the shelf or with minor modifications can meet many customers’ requirements.

In the case of the customer given a very limited time to come up with a rugged surveillance solution, the quick evaluation of system performance and environmental requirements let CP Technologies’ experienced engineering team immediately address the problem and begin work on a solution. This was possible by leveraging CP Technologies’ vast 20+ year design library containing thousands of designs covering all manner of shapes, sizes, and board configurations, many of which are already MIL-STD certified. In fact, CP Technologies has a spectrum of solutions that never requires starting from scratch. There is a range of existing products that either off the shelf or with minor modifications can meet many customers’ requirements.

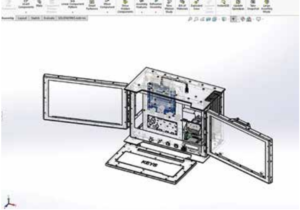

CP Technologies maintains an inventory of qualified board-level components, along with the library of design files for existing enclosure solutions that can be quickly customized before making any custom parts. (Figure 2). This makes coming up with just the right custom design a very smooth operation. This enabled the engineers to come up with a solution that met the project requirements in time to save a multi-million-dollar contract. In addition to speeding the design, the SolidWorks system also provided detailed drawings and photo-realistic images that connect to the points in the specification. These can then be presented to the customer for approval or to identify the need for further clarification. The result is the speeding of the customer approval process and moving the whole project ahead smoothly.

Building the Prototype

The goal, of course, is to produce a working, credible prototype that meets all the physical requirements for form, fit, connection and functionality that can be presented to the customer for approval and meet the requirements of their customer contract. To that end CP Technologies employs a staff of manufacturing personnel, many with over 20 years’ experience, who can perform the mechanical assembly and fit testing along with the electronic assembly and test. CP Technologies specifies custom metal and cabling work for custom assembly and brings together boards and peripherals either from its own library of approved and qualified components or from its own list of certified vendors.

The goal, of course, is to produce a working, credible prototype that meets all the physical requirements for form, fit, connection and functionality that can be presented to the customer for approval and meet the requirements of their customer contract. To that end CP Technologies employs a staff of manufacturing personnel, many with over 20 years’ experience, who can perform the mechanical assembly and fit testing along with the electronic assembly and test. CP Technologies specifies custom metal and cabling work for custom assembly and brings together boards and peripherals either from its own library of approved and qualified components or from its own list of certified vendors.

Testing includes mechanical fit, airflow and heat dissipation along with verifying the mounting of the boards along with shock and vibration testing and the fit of all electrical connectors. This process also generates documentation in terms of assembly instructions, process quality checkpoints, and test data.

The result of such a project is much more than just a prototype. It is a prototype supported by a package of documentation and a partner that together help assure the acceptance and production of the customer’s design. The design and documentation also support the life cycle and eventual needed modifications and enhancements that may be sought for the original design. CP Technologies can install additional hardware such as I/O cards to make sure they also fit with the ruggedization as well as the cable routing and required cooling. CP Technologies can also load the software in cooperation with the customer to make sure that what results is a complete product for the customer to sign off on, receive approval from their client, and ultimately send into production.

. . . and into Production

Control of the manufacturing process is maintained and supervised by CP Technologies in conjunction with its subcontractors, who, like CP Technologies, are all certified to ISO 9001:2015 quality standards. A robust quality management system is essential in consistently providing products and services that meet statutory and regulatory requirements, such as MIL-STD, among others. This also applies to the management of the supply chain through production, documentation and delivery.

One vital element of the design and prototyping process are the deliverables that accompany the prototype and help the customer quickly complete their internal processes. Mainly this is the delivery and support of documentation, which contributes to the customer’s ability to understand and maintain the design, supplies material for user manuals and provides the documentation needed for the many certifications that are often required. The aim is to support the customer’s technical documentation as well as the documentation required by their customer and government agencies for certification and acceptance.

The ability to transmit three-dimensional CAD files and other engineering drawings both during the design phase, as well as during production and product delivery, allows a rapid exchange of information between CP Technologies and their customer. STEP files are analogous to .pdf files in that they can be converted to other format for use in prototype dimensional checks, as well as during technical documentation such as a customer’s in-situ installation of system in shipboard or aircraft environments.

The ability to transmit three-dimensional CAD files and other engineering drawings both during the design phase, as well as during production and product delivery, allows a rapid exchange of information between CP Technologies and their customer. STEP files are analogous to .pdf files in that they can be converted to other format for use in prototype dimensional checks, as well as during technical documentation such as a customer’s in-situ installation of system in shipboard or aircraft environments.

In addition, the large effort used to gather the information and data earlier in the process lets them now be assembled into reports and formatted documents to meet the necessary standards and certification requirements. These include the MTBF information, the letter of volatility, counterfeit material and conflict mineral statements, TAA documentation and other required material as applicable.

The process that began with the identification of sharply specific requirements as opposed to general requirements then becomes one of setting and realizing goals starting with component selection and qualification, establishment of a clear plan of action, detailed design and engineering and manufacture. All the while clear communication with the customer ensures agreement and parallel effort to accommodate changes and maintain understanding and rigorous documentation supports meeting requirements for delivery of a rugged prototype that can be quickly accepted, certified and manufactured to assure success.