Mil-Std-810G is a United States Military Standard that emphasizes tailoring an equipment’s environmental design and test limits to the conditions that it will experience throughout its life. In other words, except for some specific and carefully crafted test specifications, 810G leaves it up to the equipment manufacturer and the end user to define a test methodology.

The Specification is 804 pages and is administered by a Tri-Service partnership including the USAF, US Army and the US Navy. Revision ‘G’ was released October 31, 2008. Revision ‘F’ was released January 1, 2000.

The standard’s guidance and test methods are intended to:

- Define environmental stress sequences, durations, and levels of equipment life cycles

- Be used to develop analysis and test criteria tailored to the equipment and its environmental life cycle

- Evaluate equipment’s performance when exposed to a life cycle of environmental stresses

- Identify deficiencies, shortcomings, and defects in equipment design, materials, manufacturing processes, packaging techniques, and maintenance methods

- Demonstrate compliance with contractual requirements

The Specification is broken into 3 Parts. Part One describes management, engineering and technical roles in the environmental design and test tailoring process. Part Two contains the environmental laboratory test methods to be applied using the test tailoring guidelines described in Part One of the document. Part Three contains a compendium of climatic data and guidance assembled from several sources.

Note, in Part Two, with the exception of Test Method 528, these methods are not mandatory, but rather the appropriate method is selected and tailored to generate the most relevant test data possible. For example, many manufacturers state they meet Mil-Std-810G for operating temperature and list a range of, for example, 0 to 60 deg C. But a close examination of 810G will not reveal any published test method listing those limits. The manufacturer has crafted a plan to prove to the end user that their equipment does, in fact, operate within that temperature range and can thus claim compliance with 810G. Other companies will claim compliance with 810G when they have simply subjected that piece of equipment to a single test such as Test Method 514.6 (US Highway Truck and Air Transport) wherein the equipment is packaged in a box or transit case with foam padding as it would be given to UPS.

The Specification is broken into 29 Sections or Test Methods, each covering a different aspect of environmental exposure as listed below.

- Test Method 500.5 Low Pressure (Altitude)

- Test Method 501.5 High Temperature

- Test Method 502.5 Low Temperature

- Test Method 503.5 Temperature Shock

- Test Method 504.1 Contamination by Fluids

- Test Method 505.5 Solar Radiation (Sunshine)

- Test Method 506.5 Rain

- Test Method 507.5 Humidity

- Test Method 508.6 Fungus

- Test Method 509.5 Salt Fog

- Test Method 510.5 Sand and Dust

- Test Method 511.5 Explosive Atmosphere

- Test Method 512.5 Immersion

- Test Method 513.6 Acceleration

- Test Method 514.6 Vibration

- Test Method 515.6 Acoustic Noise

- Test Method 516.6 Shock

- Test Method 517.1 Pyroshock

- Test Method 518.1 Acidic Atmosphere

- Test Method 519.6 Gunfire Shock

- Test Method 520.3 Temperature, Humidity, Vibration, and Altitude

- Test Method 521.3 Icing/Freezing Rain

- Test Method 522.1 Ballistic Shock

- Test Method 523.3 Vibro-Acoustic/Temperature

- Test Method 524 Freeze / Thaw

- Test Method 525 Time Waveform Replication

- Test Method 526 Rail Impact

- Test Method 527 Multi-Exciter

- Test Method 528 Mechanical Vibrations of Shipboard Equipment (Type I – Environmental and Type II – Internally Excited)

Future CP Technologies blog entries will examine each of these sections in depth.

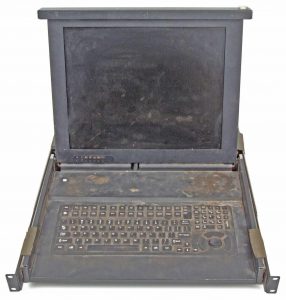

CP Technologies designs and tests as appropriate their Military Grade computer and LCD display products to meet or exceed the limits of Mil-Std-810G. We work closely with the customer to define a test standard that assures continued reliable operation of their entire deployed system in the intended environment.